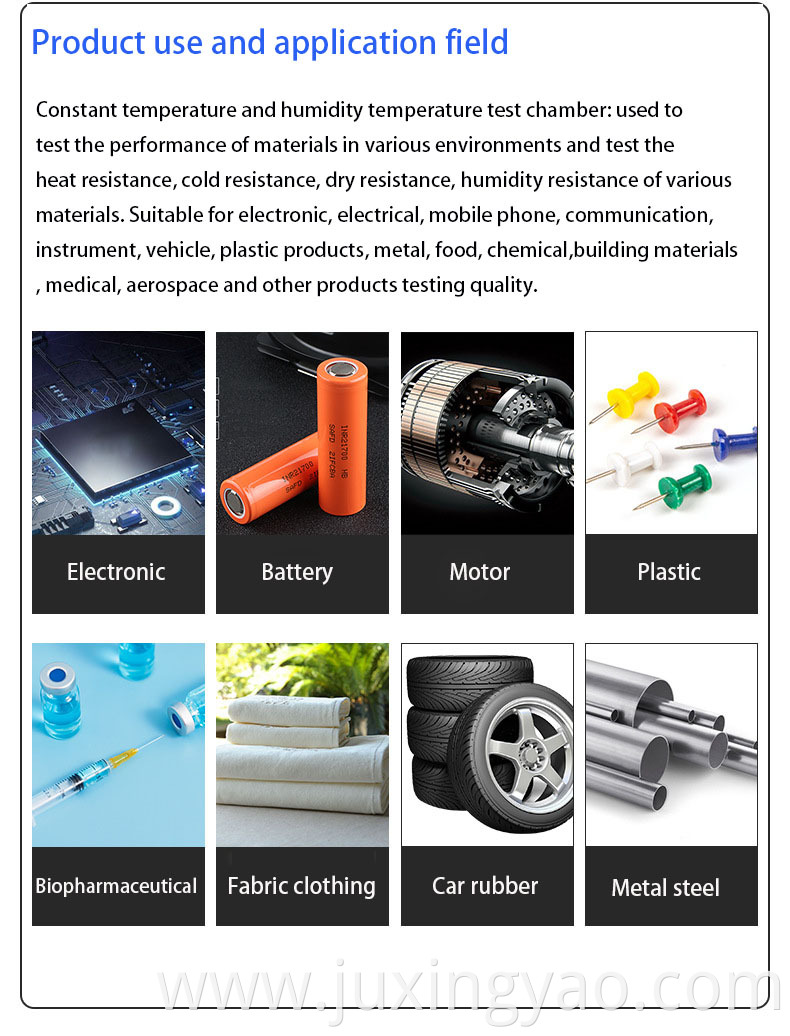

Function and function of constant temperature and humidity chamber The function of constant Temperature And Humidity Test Chamber is: Equipment for testing the performance of materials in various environments and testing the heat resistance, cold resistance, dry resistance and moisture resistance of various materials. It is a necessary test equipment for aviation, automobiles, home appliances, scientific research and other fields. It is used to test and determine the parameters and performance of electrical, electronic and other products and materials after the temperature environment changes in high temperature, low temperature, alternating humidity and heat degree or constant test.

| Model | GDS-50 | GDS-100 | GDS-150 | GDS-225 | GDS-408 | GDS-800 | GDS-010 |

| System | Balanced Temperature & Humidity Control System |

| Temp.Range | -20℃~150℃;-40℃~150℃;-70℃~150℃

Rapid temperature nolinear (Linearly is option) |

| Humidity Range | 20~98%R.H |

| Temp.fluctuation | ±0.5℃ |

| Humidity Fluctuation | ±2.5%R.H |

| Temperature Deviation | ±2.0℃ |

| Humidity deviation | ±3%R.H(≥75%R.H)/±5%R.H(<75%R.H) |

| Heat Up Time | -20℃~150℃ about 40 minutes ,-40℃~150℃ about 60 minutes,-70℃~150℃ about 75 minutes |

| Pull Down Time | 20℃~-20℃ about 40 minutes ,20℃~-40℃ about 60 minutes,20℃~-70℃ about 85 minutes |

| Internal dimension | W | 350 | 500 | 500 | 600 | 680 | 1000 | 1000 |

| H | 450 | 500 | 600 | 750 | 800 | 1000 | 1000 |

| D | 300 | 400 | 500 | 500 | 750 | 800 | 1000 |

| External dimension | W | 550 | 700 | 700 | 800 | 880 | 1200 | 1200 |

| H | 1450 | 1550 | 1610 | 1710 | 1760 | 1950 | 1950 |

| D | 1000 | 1150 | 1250 | 1250 | 1500 | 1550 | 1750 |

| Interior material | SUS#304 Stainless steel plate |

| Exterior material | Backed painting steel or stainless steel(SUS304) |

| Insulation material | Rigid polyurethane foam + glass fibre |

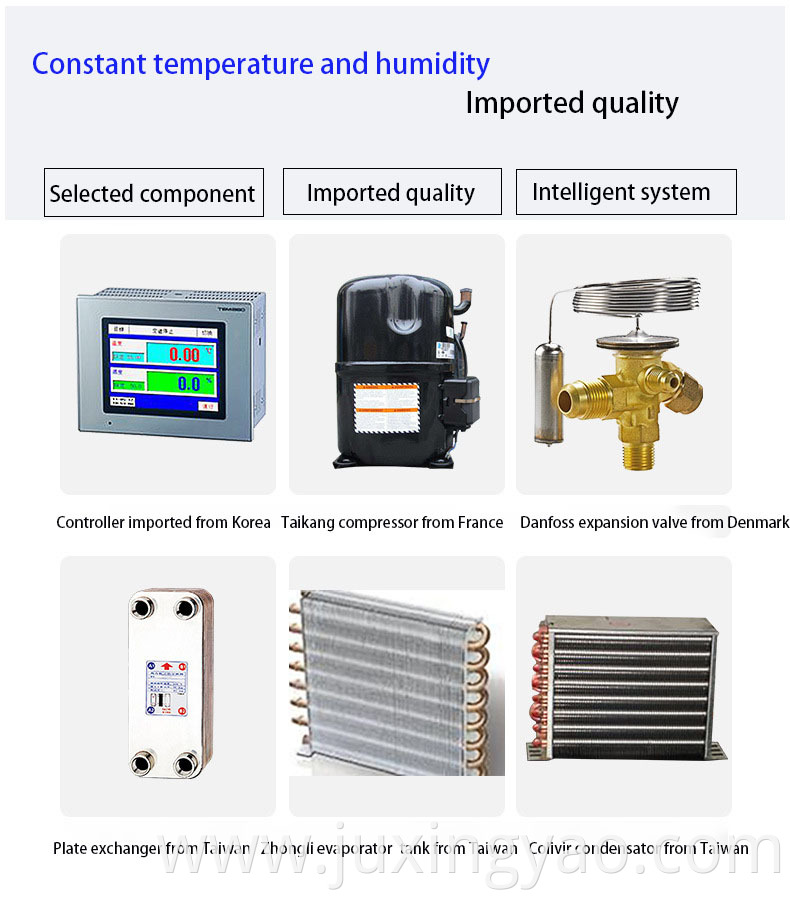

| Refrigeration system | Air cooled or (Water cooled type is option) |

| Single section/Cascade type,Hermetic/Semitight compressor,CFC free refrigerant |

| Controller | Color LCD screen in English/Chinese.programing communicating function |

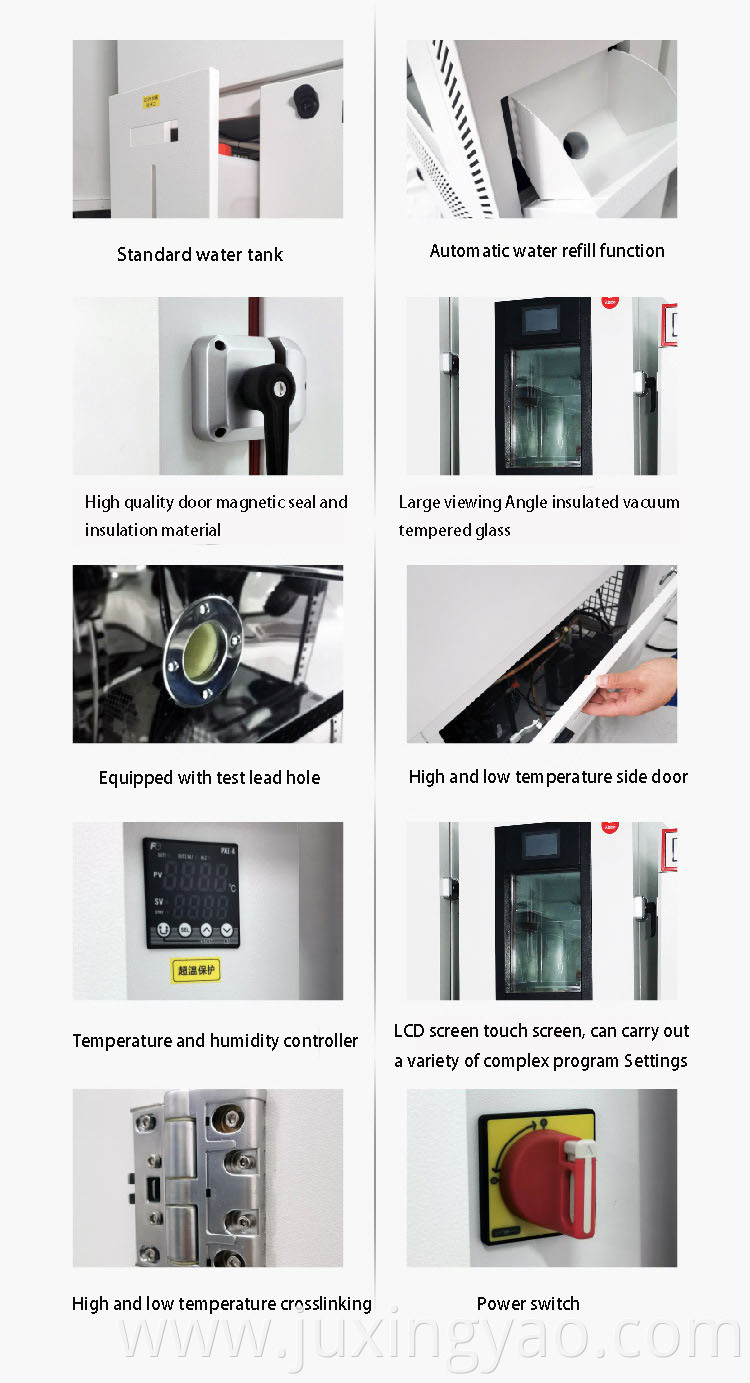

| Safety Devices | No welding wire switch,compressor overheating and over current protection,over pemperature protection,blower overload protection,dry heating machine protector,low water protection,fault warning system |

| Standard Accessories | one observation window,one test hole(Φ5cm),two sets of test racks,one floodlight,one indicator light,four moving wheels,one humidifying tank,2 meters of power cord,communication interface |

| Ambient Temp. | 5℃~35℃ |

| Power | AC380±10% 50HZ 3 phase 4wires+Groud wires |

| Note: The above specifications are for reference only, the actual specifications are mainly quoted |